Sugaring Season

View a sample of photographs that capture the season from collecting sap, to making syrup. Enjoy!

Making Syrup

The sap from our trees averages just under 2% sugar content, which means it takes us about 50 gallons of sap to produce one gallon of syrup! Rather than use the evaporator to remove all that water from the sap, we utilize a reverse osmosis machine. This wonderful piece of equipment forces the sap through special membranes under high pressure to “squeeze” the water out of the sap, resulting in concentrated sap containing 13% sugar. Instead of boiling 50 gallons of sap, we now have to boil only 7! The excess water is captured and later used to clean the equipment. The concentrated sap runs through a specialized hood, known as a “Steamaway”, which sits on the back of the evaporator. The Steamaway not only preheats and further concentrates the sap, but it also produces large volumes of hot water that we capture and use for cleaning. When the evaporator is running at full capacity we can produce over 20 gallons of syrup per hour. The syrup is drawn off the evaporator at 219 degrees and run under pressure through a filter press to remove any impurities, resulting in sparkling clear maple syrup.

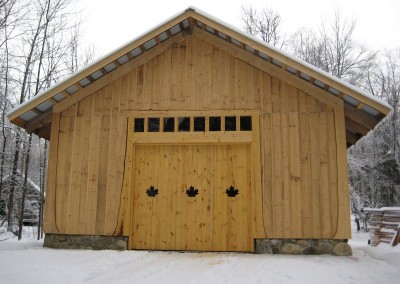

The Sugarhouse

Our hand-crafted sugarhouse is built like the Northeast Kingdom… rugged. The frame of spruce and hemlock, cut from our own woods, sits on a stone foundation made of rocks collected from a neighboring farmer’s fields. It is a stone’s throw from the site of the original “Ozzie Camp” built in 1943, where generations learned the ways of the northern forests. The old wood-fired cook stove from that camp now sits in the corner of the sugarhouse, warming us with soft heat and fond memories.

The Woods

Old sugarmakers have always said that you don’t make your money in the sugarhouse, you make it in the woods, meaning that if you do not properly manage your woods and sap delivery system, you are wasting your time. Installing and maintaining 20 miles of pipeline to deliver sap from 4,000 trees in a 45-acre area is quite a job. The pipeline system is connected to a vacuum pump to increase the pressure differential in the tree, which produces more sap than the traditional buckets. Our 7.5 horsepower liquid ring vacuum pump is controlled by a variable frequency drive, which can sense leaks in the pipeline system. When the pipeline is leak free, the pump will reach 27 inches of mercury and maintain that level at with minimal effort. If a falling tree limb, or wandering moose, breaks a line, the drive increases power to pump in an effort to purge the influx of air into the system, which sends us to the woods to locate and fix the problem. Small leaks are much more common. The freeze-thaw cycles, that we depend on to produce sap, also result in taps working their way out of the tap hole. Squirrels, woodpeckers and coyotes make holes in the lines. We are constantly on “leak patrol”, which entails carrying a wide range of tools and fittings through the woods, using valves and gauges to isolate problem areas, listening for the hiss of a vacuum leak, and re-seating loose taps back in the tree.

Community and Family

The Northeast Kingdom is a place of unmatched beauty, tight-knit communities, and families that date back to the early settlers. As active members in our community, Osborne Family Maple is proud to carry forward the traditions and values that make this place so special. If you have never visited Island Pond, come visit us at the sugarhouse sometime, or catch the 4th of July parade to see what you are missing!